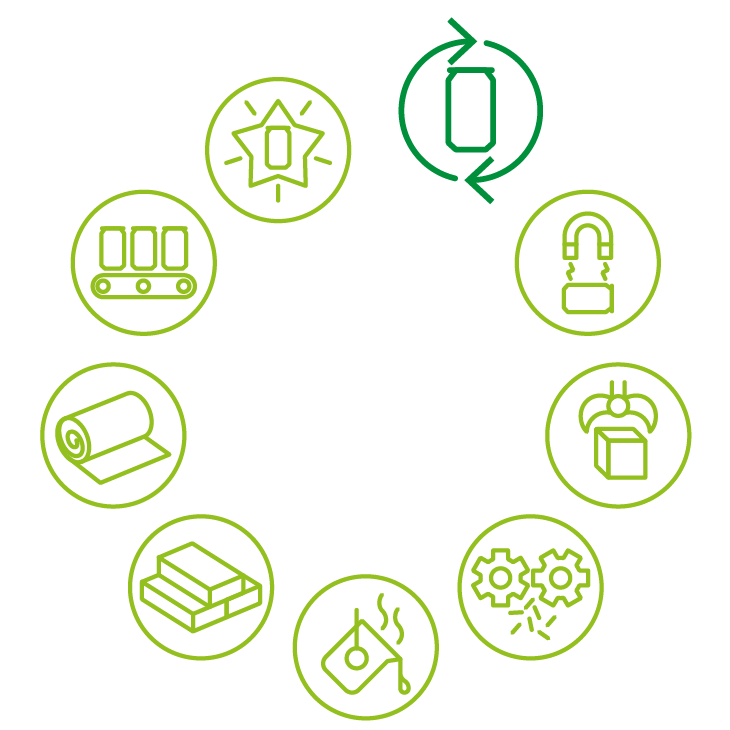

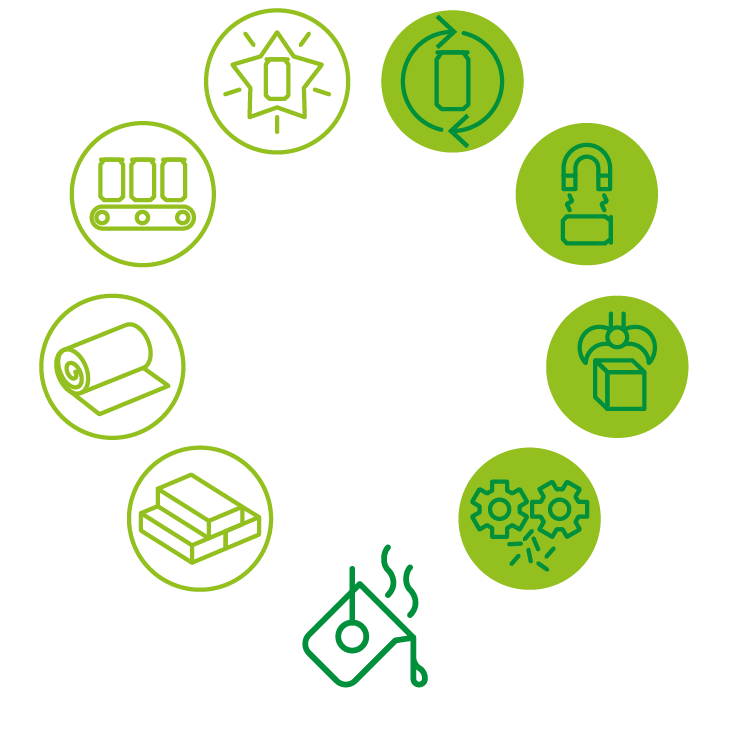

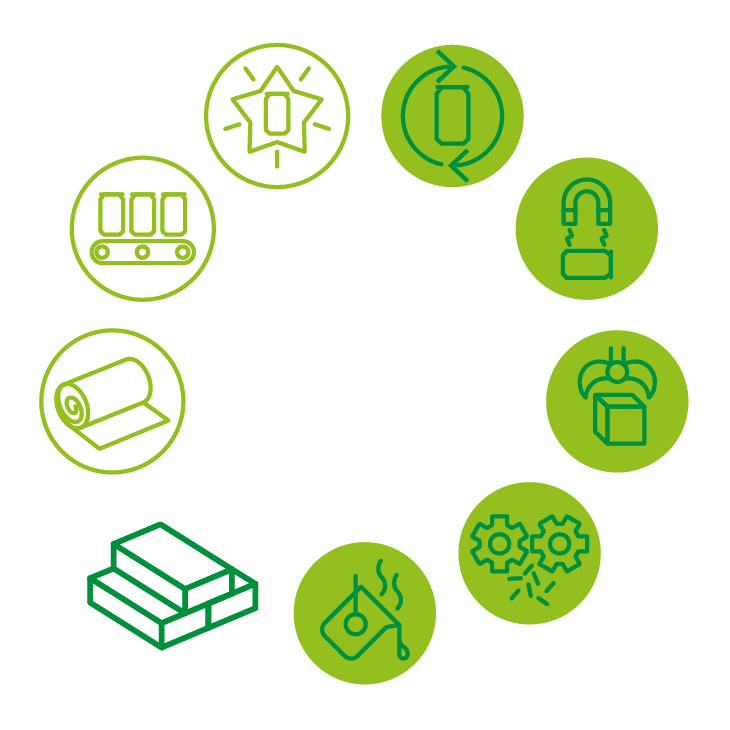

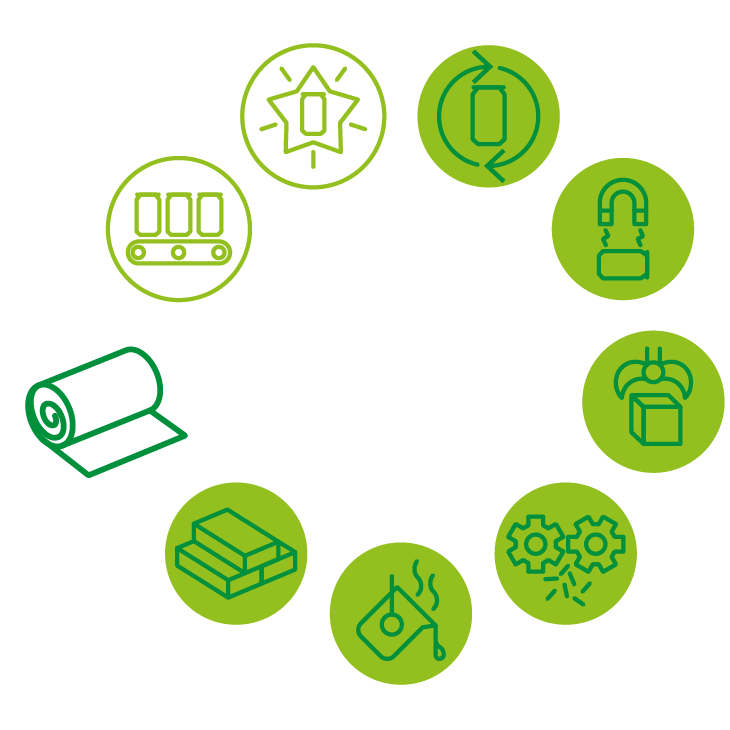

LIFE CYCLE

of a Can

CAN RECYCLING

Embark on a journey

that never ends

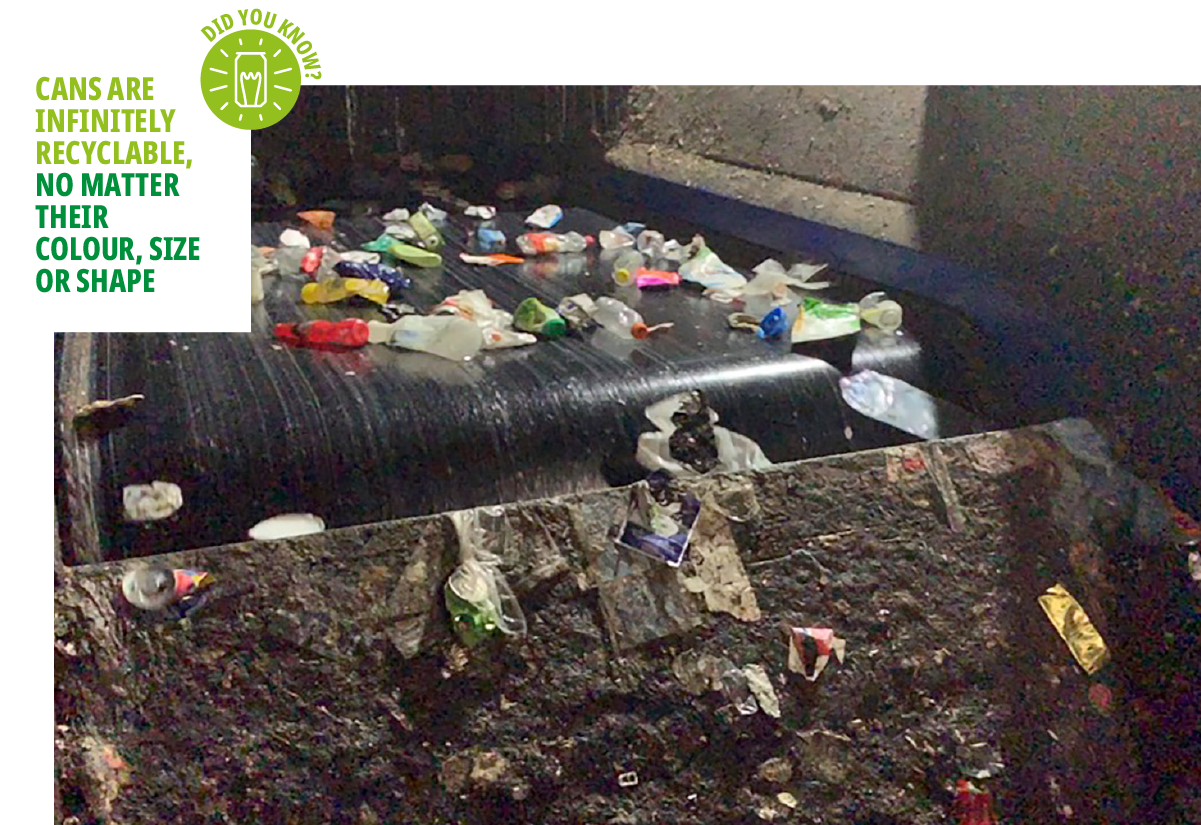

Collection

The first step is to collect the cans. If they’re not collected, then they can’t be recycled.

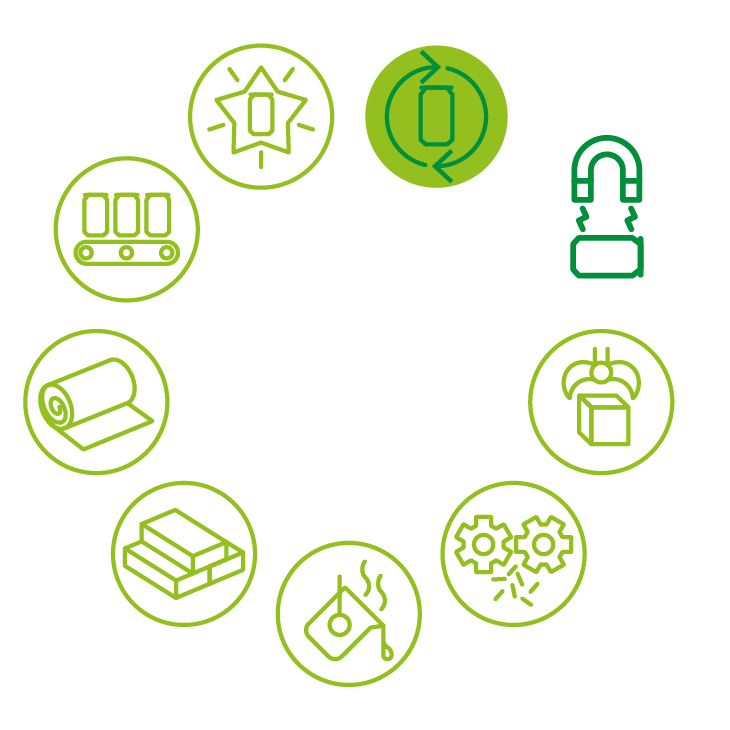

Sorting

Cans go to a sorting centre, where they’re separated from other materials using electric currents (known as eddy currents).

Baling Up

Separated cans are baled up into large, heavily compressed cubes and sent to a recycling plant.

Shredding

Bales of cans are shredded into smaller pieces. Any steel particle left is removed with the help of a regular magnet and aluminium is then further isolated by eddy currents (also called Foucault’s currents).

Remelting

The shreds are heated so the decoration can be removed by blown air. The energy released by this process is recovered therefore minimising the initial input of energy.

Ingot Casting

At the recycling plant cans are melted and shaped into huge aluminium blocks. No rocket science here, just re-melting!

Rolling

The blocks are rolled into thin sheets and coils, from which they’re made into new cans.

Manufacturing

Drink cans are manufactured by shaping aluminium into a cylindrical shape.

Beverage cans

Cans are printed at tremendous speed with extreme accuracy. They are now ready to be filled and put back on sale.

AND EVERYTHING STARTS AGAIN!

The whole process is incredibly quick – old drink cans become part of a new bike, car, coffee pot or even new cans within 60 days of being collected. And every drink can can be recycled over and over again, forever.

Let’s recycle every can consumed

Each and every one of them can be recycled and back on sale in just 60 days.